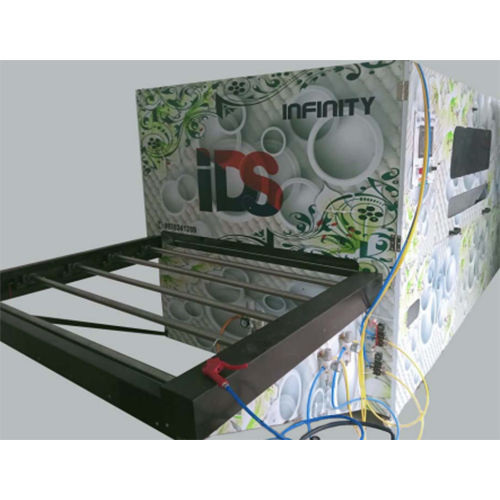

UV Coating Machine

Price 800000 INR/ Piece

UV Coating Machine Specification

- Product Type

- UV Coating Machine

- General Use

- Industrial UV coating applications

- Material

- Mild Steel/Stainless Steel

- Type

- Automatic

- Weight (kg)

- Approx. 1200 kg

- Coating Speed

- 15-60 m/min

- Coating Head

- Roller Coater

- Coating Width

- Up to 1200 mm

- Coating Material

- Paper, Board, PVC Sheets

- Computerized

- Yes

- Automatic

- Yes

- Control System

- PLC based HMI Control

- Power Source

- Electric

- Power Consumption

- Approx. 8-12 kW

- Heating System

- UV Lamp Heating

- Drive Type

- Electric

- Voltage

- 380V/415V, 50 Hz

- Humidification System

- Not Equipped

- Glue Type

- UV Curable Coating

- Rewinder Type

- Automatic

- Unwinder Type

- Manual/Auto (as per model)

- Rewinding Width

- Up to 1200 mm

- Unwinding Width

- Up to 1200 mm

- Dimension (L*W*H)

- 5000 x 1500 x 1650 mm

- Feature

- High gloss finish, instant drying, energy efficient

- Color

- Blue & Grey

- Application

- Magazines, book covers, packaging, labels, brochures

- Max. Coating Thickness

- 25 microns

- UV Lamp Power

- 1 x 7 kW (Customizable)

- Cooling System

- Air cooled/Chiller (As per requirement)

- Max Sheet Size

- 1200 x 900 mm

- Feeding Type

- Automatic Feeder

- Safety Features

- Emergency stop, interlock safety covers

- Noise Level

- <75 dB(A)

- Min Sheet Size

- 300 x 400 mm

- Number of Rollers

- 3

UV Coating Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Week

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

About UV Coating Machine

With an aim to be a leader in the market, we are serving our respected clients by manufacturing, supplying, and exporting UV Coating Machine. It is engineered and fabricated at our state-of-the-art production unit under good guidance of a team of professionals. This machine is widely used to apply UV coatings on different products that provide high lustrous gloss and prevent from rubs/scratches. We fabricate this UV Coating Machine using only high-grade raw materials that ensure highly durable and flawless machine.

Features of UV Coating Machine:

- Low power consumption

- Exchangeable pattern rollers

- Coating can be applied in different widths

Mfrs. of : Non Wowam Printing Machine, paper Printing Machine, Poly Bag Printing Machine, UV Coating,UV Curing System, Automatic Lamination Machine & Paper Cutting Machine etc.

DPL is Indias leading company engaged in manufacturing of full range of UV Coating and Curing Systems& Screen Printing Machines. The company is located in Faridabad, an industrial town, in the out skirts of Faridabad. It has fully equipped modern factory.

DPL Machinery fully automatic coater & curing system model solna type Indian Machinery. This Machine includes all technical solution for easy operation and for Increasing Productivity. The Machine is compact solid built on a strong C.l. Frame, It is relable at any Working speed. This Machine machine is equipped with high grade hardened grounded gears for its smooth operation for year.

The UV curing lamp used in it are one of the best in the world. It consist of total vacuum bed for smooth curing of paper efficient cooling system for lamps.

Application of UV Coating Machine:

- Precise registration of high speed using precision adjustable side and front lay.

- Powerful stream feeder to handle stock from 30 g.s.m. to 400 g.s.m.

- User adjustable Double sheet Detector.

- Delivery convear steeker table automatically up down with paper setting.

- Three roller attachment & Two Cylinder

- Streat Arm gripper for high speed is accurate registration

- Speed maximum 8000 per hour

- Plate Clamps suitable for clamping blanket or photopelymer plates.

Specification of UV Coating Machine:

|

Description |

15x 20 |

18 x 25 |

20 x 30 |

23x 36 |

28x 40 |

|

Paper Size Max |

386 x 515 mm |

460 x 640 mm |

510 x 770 mm |

585 x 915 mm |

715 x 1020 mm |

|

Paper Size Min |

210 x 250 mm |

230 x 280 mm |

305 x460 mm |

305 x 460 mm |

305 x460 mm |

|

Printing Area |

370 x 505 mm |

445 x 635 mm |

495 x 750 mm |

570 x 900 mm |

700 x 1005mm |

|

Gipper Margin |

9mm |

9mm |

9mm |

9mm |

9mm |

|

Running Speed Max |

8000 rph |

8000 rph |

7000 rph |

6000 rph |

6000 rph |

FAQs of UV Coating Machine:

What is UV covering machine?

An UV covering machine is utilized to apply the covering in the wake of printing. UV coatings can differ in reflectivity and thickness, contingent upon the application, however a serious shine or unpretentious matte UV covering are regularly utilized for premium printing applications.

Is UV covering great?

Much of the time, yes. Pick shades that offer 100 percent UV security and will likewise retain a large portion of the unsafe blue light, otherwise called HEV beams. Adding an UV covering to your eyeglasses might do the trick to sift through destructive blue light too.

What is UV covering utilized for?

UV Covering is an intense clear-coat applied over printed materials to 1) safeguard against scratches, tears and fingerprints and 2) upgrade the brightness of the ink tones.

Precision Industrial UV Coating

Optimized for a wide range of substrates, this UV Coating Machine ensures consistent high-gloss finishes on paper, board, and PVC sheets. Its roller coater technology and computer-controlled operations deliver uniform coating thicknesses up to 25 microns, making it ideal for premium print and packaging applications.

Customizable and Efficient Operation

Featuring an automatic feeder, customizable UV lamp power, and a PLC-based HMI control system, this machine streamlines the coating process while offering flexibility for specific production needs. The air-cooled or chiller-based cooling system can be adapted as required, guaranteeing optimal performance.

Safety and Environmental Considerations

Equipped with emergency stop functions and interlock safety covers, safety is at the forefront of this UV coating machine's design. Its energy-efficient operation, low noise levels, and instant drying capabilities help promote a safer and cleaner work environment.

FAQ's of UV Coating Machine:

Q: How does the UV Coating Machine handle different sheet sizes and materials?

A: The machine accommodates sheets ranging from 300 x 400 mm up to 1200 x 900 mm and is suitable for paper, board, and PVC sheets. Its automatic feeder ensures smooth handling and processing of various sizes and material types.Q: What is the process for achieving high-gloss, instant drying finishes with this machine?

A: The coating is applied by a roller coater and cured using a UV lamp powered at 7 kW (customizable). The UV curable coating instantly dries when exposed to the UV lamp, delivering a high-gloss finish efficiently.Q: When should the cooling system be customized to suit production needs?

A: The cooling system can be switched between air-cooled and chiller options based on operational requirements, volume, and ambient temperature. Chillers are recommended for high-volume or extended runs to manage heat effectively.Q: Where can this UV Coating Machine be installed for optimal workflow?

A: Ideally, the machine should be installed in industrial print facilities or packaging units with adequate space (5 x 1.5 x 1.65 meters) and proper ventilation to accommodate its size, power requirements, and operational safety.Q: How does the PLC-based HMI control system enhance usage and efficiency?

A: The PLC-based HMI control system allows operators to easily set and monitor machine parameters, improving accuracy and reducing setup time. Computerized controls ensure consistent results and streamline operation, especially in industrial environments.Q: What are the main benefits of using this UV Coating Machine for industrial applications?

A: Key benefits include instant drying, high gloss finish, energy efficiency, safety features, and the flexibility to process various substrates and sizes. Its robust design supports continuous, high-speed production for diverse coating applications.Q: Is regular maintenance required for the UV Coating Machine, and what should be checked?

A: Yes, regular maintenance is recommended. Operators should check roller and lamp condition, ensure safety covers and emergency stop functions are operational, monitor cooling system performance, and inspect PLC control systems for consistent output.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in UV Coating Machines Category

Automatic UV Coating Machine

Price 850000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Rewinder Type : Single Rewinder

Unwinder Type : Lifting Unwinder

Warranty : 1 year

Voltage : 440 Volt (v)

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese